Global manufacturer of thermoformed packaging, automotive

and material handling solutions.

Industry-Leading Thermoforming Solutions

Manufacturing and Material Handling

01 /

What we do

TriEnda is a U.S. based global manufacturer of thermoformed packaging and material handling solutions. With a heritage of over 40 years of industry expertise, excellent custom designs, and experienced teams, TriEnda leads the thermoforming industry in innovation and service.

As the industry’s largest thermoformer, we also lead the market in providing single and twin sheet thermoformed plastic solutions to the material handling and packaging industries. With experience working alongside grocery, food service, retail, automotive, government, and healthcare organizations, TriEnda has a multitude of products already created and ready-to-ship alongside our custom solutions created by our experienced engineering and design teams.

Explore our capabilities, ask about our custom solutions, and upgrade your material handling experience by working with TriEnda.

02 /

Featured Products

EASY CLEAN

SANITARY

WEATHER RESISTANT

RECYCLE

03 /

Industries Served

For over 40 years TriEnda’s experienced team of professionals has been leading the way in material handling solutions and custom products.

Our award-winning process and design solutions including patents on several innovative and cost-effective products allows our customers to trust the quality of every TriEnda product. Our organization is committed to quality, and proud to be ISO 9001:2015 Certified.

04 /

Resources

Kruger Family Industries (KFI) is a finalist for the 35th Annual Wisconsin Manufacturer of the Year Award in the mega category. The Wisconsin Manufacturer of the Year program acknowledges and

TriEnda’s NEW Steel Rack Material Handling Facility

What is Steel Racking? To keep it simple, steel racking provides strength to ship and protect an item during travel. Due to their strength and durability, steel racks are designed

How Kruger Family Industries Prioritizes Sustainability

What is Sustainability? When you hear the word sustainability, what comes to mind? Most people associate the word with long lasting or environmentally friendly. Now, when you hear the word

Meet Our Team: Todd Spencer

The Meet Our Team blog series gives you an inside look into our team members’ careers, exciting new projects, history with KFI, and a general introduction to some of our key

TriEnda and Good360: A partnership in Charity

TriEnda has donated 5,000 emergency mattresses to be distributed by charity organization Good360. TriEnda created emergency hospital beds during the Covid-19 Pandemic to help accommodate the overcrowding in medical facilities.

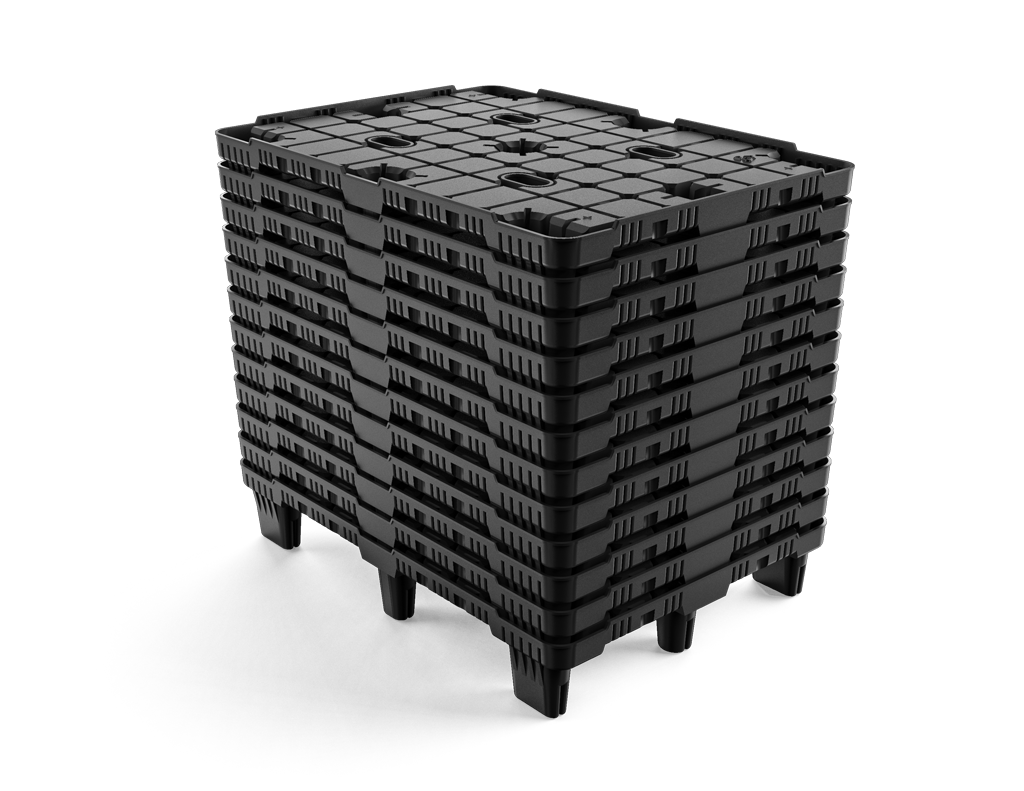

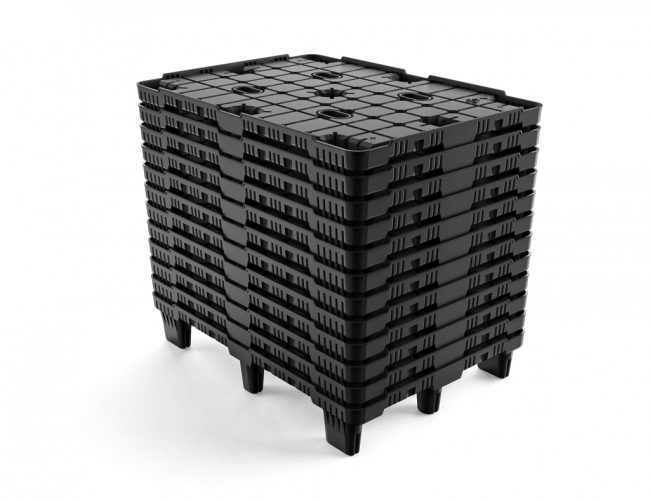

Advantages of BigPak® Sleeve Packs

Discover the advantages of the dependable TriEnda BigPak® Sleeve Packs. Among many of TriEnda’s durable, HDPE, material handling solutions are our BigPak® Sleeve Packs. These reusable bulk containers lower costs

Meet Our Team: Pieter Lesterhuis

The Meet Our Team blog series gives you an inside look into our team members’ careers, exciting new projects, history with KFI, and a general introduction to some of our

Advantages of Load Lockers

Safeguard your product with TriEnda’s Load Lockers! Protecting your cargo is what TriEnda is all about, this may be with durable pallets, Cargo Protect+ solutions, or Load Lockers. Our Load

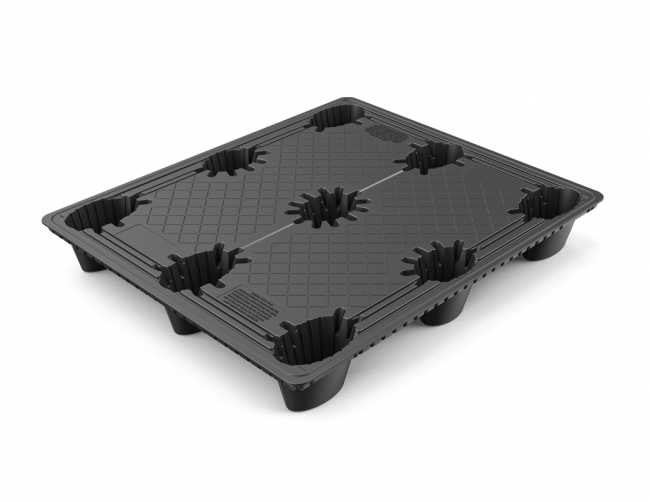

Advantages of the One-Way Pallet

Learn why the One-Way pallet could change the way your ship products. Looking for a solution to your single-leg shipping needs? The TriEnda One-Way Pallet is the sanitary, safe, durable,

Meet Our Team: Sue Malkowski

The Meet Our Team blog series gives you an inside look into our team members’ careers, exciting new projects, history with KFI, and a general introduction to some of our