Development

Protoyping

01 /

Development

An important part in the design and manufacturing process is prototyping. TriEnda takes this step very seriously in efforts to reduce development time and costs and ensure a smooth rollout of your custom plastic products.

Our highly skilled engineering team works closely with you from concept and design, to testing and implementation to guarantee you’re satisfied before making any substantial system changes. This step ensures that you save time and money and we take prototyping very seriously to create the best possible product and save your organization from wasted time and money.

Improved Efficiency and Satisfaction

Prototype Development

Reduce development time and costs and ensure a smooth rollout of your custom plastic products by investing in prototyping. Our highly skilled engineering team works closely with you from concept and design to testing and implementation to guarantee you’re satisfied before making any substantial system changes.

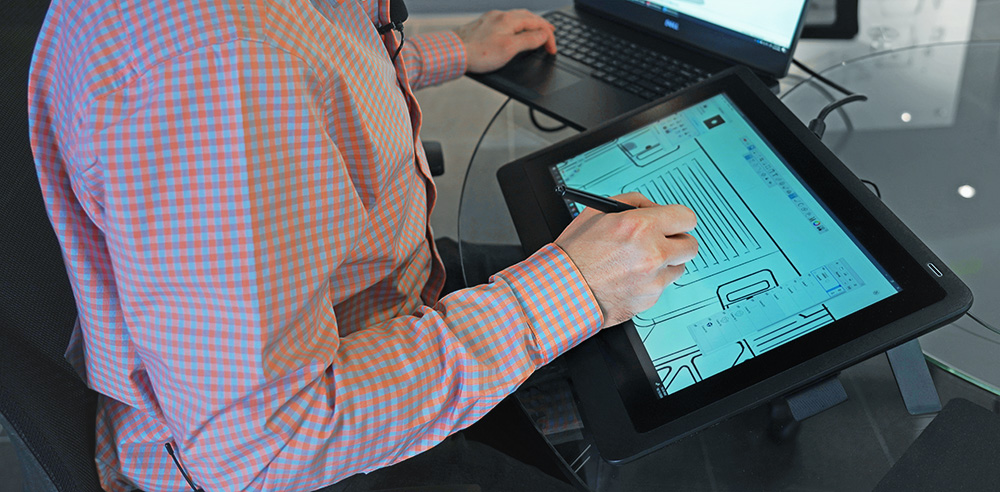

DESIGN

02 /

Advantages

CAD MODELING

Taking all aspects into account, sketches are turned into CAD models so that they can be molded into a final product.

Smooth Rollout

TriEnda works with you every step to make sure that the prototypes are developed to your specifications.

Save Time

Utilizing the talented engineering team and our production facilities, your design will be tested thoroughly and quickly.