We’re revealing the science behind our latest discovery called TruGrip™ and its dramatic effect on surface friction.

The logistics industry has struggled with slippery pallets for a long time. Low friction between pallet top and carton, tote, or other container has caused countless spills, led to many accidents, and cost a great deal of money.

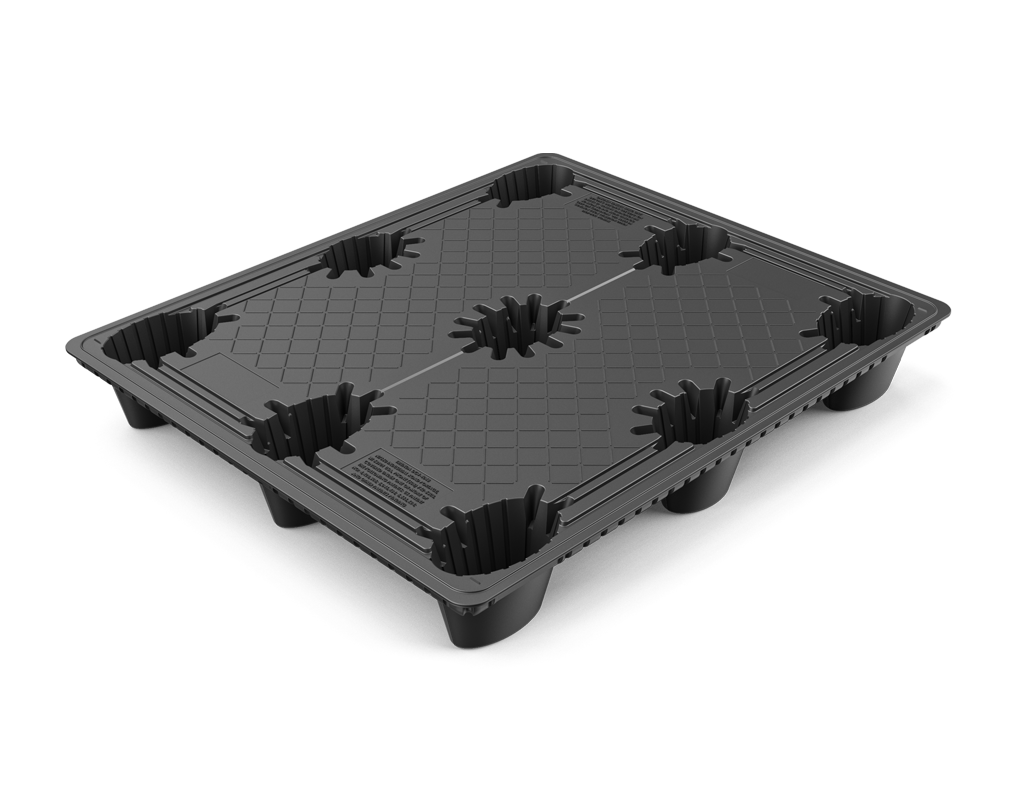

The latest discovery of a revolutionary product called TruGrip™ solves this problem. This proprietary plastic formulation increases friction between the top of a pallet and the load placed on it. By increasing the force needed to make a container slide, TruGrip dramatically improve load security, paving the way for non-slip pallets that reduce accidents and spills. In this post, discover what it does and how it was created. But first, a little background on plastic.

The appeal of plastic for pallets

Plastic pallets are durable, relatively clean, and weather resistant. They don’t absorb dangerous chemicals and harbor bacteria, and they can be reused 10-12 times more than wood. They can even be recycled. These qualities make them attractive to many different industries, especially those deciding between plastic vs. wood pallets.

For users with delicate cargo, the relatively low friction between pallet surface and load has been challenging. Sudden starts and stops can make the load slide on the pallet. In extreme cases, the load may even slide off the pallet completely. Clearing up the resulting spill takes time and disrupts operations and may result in product loss or potential health and safety issues.

The inspiration behind TruGrip non-slip pallets

Pickup trucks suffer with this same sliding problem. Drop a toolbox in the bed, and it’ll slide in every direction, damaging both box and bed. To counter this problem, many truck owners use a bed liner. Our development team observed how a liner reduces sliding by increasing friction. They also noticed that slip-resistant liners tend to deteriorate quickly. What if, they reasoned, it was possible to develop a longer-lasting, more durable version of a bed liner for pallets? To answer this central question, we took to a deep dive in the areas of friction science and hardness and durometer on our quest to develop a revolutionary non-slip pallet option.

Friction science

Friction is a complex phenomenon and is very much dependent on surface hardness, texture, and ductility. At a microscopic level, every surface has a texture with high and low points. When two surfaces are brought together, it’s these high points (scientists call them asperities) that touch. Try to slide one surface over the other, and the asperities mesh together to resist movement. Friction depends on how readily they break or bend, which is the connection back to hardness and ductility.

There are two main types of friction: static and dynamic. Static friction resists the start of motion while dynamic is the force needed to keep an object sliding. Static friction is higher because it takes more effort to start something sliding – and once it’s moving, you have momentum on your side.

Hardness and durometer

Most friction models discuss it in terms of metals, particularly steel. Plastics behave slightly differently because they’re not as hard. For both types of material, hardness is measured by indentation: press a sharp point into the material and see how much of a mark it leaves. The tricky aspect of plastics, though, is that they spring back, so indentation is measured slightly differently.

The device used is a durometer. This plastic indentation measurement tool has a cone that’s pushed into the plastic by a known load. Rather than measure the indentation made (because there isn’t one), hardness is determined by how deep the cone penetrates. This data is given as a single “Shore” hardness number, named after the method’s inventor, Albert Shore.

The creation of TruGrip non-slip pallets

A high-friction plastic surface needs a specific combination of durometer, ductility, and texture. Recognizing these key factors was just the start of a years-long development effort.

First, the multi-disciplinary development team set about finding materials that would blend with the high-density polyethylene (HDPE) we use to achieve the target durometer number. Samples came from six different manufacturers in four different countries, and each was subjected to meticulous analysis.

Having narrowed down the list of candidate materials, we took the next step: extensive laboratory testing. This phase was a slow, methodical process of mixing and extruding different combinations. Each one then goes through extensive mechanical testing to determine how it will behave in the real world. Finally, the team compared the results and identified the best sets of materials for TruGrip non-slip pallets.

With the materials chosen, production feasibility assessment came next. Many of the trials were unsuccessful, but eventually, the team arrived at a material combination that satisfied both performance and manufacturing requirements. Then, a full-scale trial began. Only after this trial had verified that TruGrip could be produced consistently in volume – and that it would perform as required – could the product be launched.

Tailored friction

For hardness testing, our trials verified that durometer depends on the load applied. This value is fixed, but in the real world where TruGrip will be used, it varies. Some cartons, totes, or sacks will be heavier than others. If TruGrip came in only a single durometer value, the heavier containers would sink in much further than the lighter ones.

To avoid this problem, part of the development effort addressed the ability to tailor durometer. The result is that TruGrip non-slip pallets are available in a range of hardnesses to suit the pallet application.

Eliminating the slip

Plastic pallets are an ever-growing choice in automotive, manufacturing, and logistics. What’s been missing is a lower friction surface to prevent load sliding. TruGrip is an innovation in plastics technology that lets us tailor durometer to suit the load. The result: the next generation of non-slip pallets!

To learn more about TruGrip non-slip pallets and how they can help reduce damage and loss, contact our sales team at 800.356.8150 or reach out to us online today.