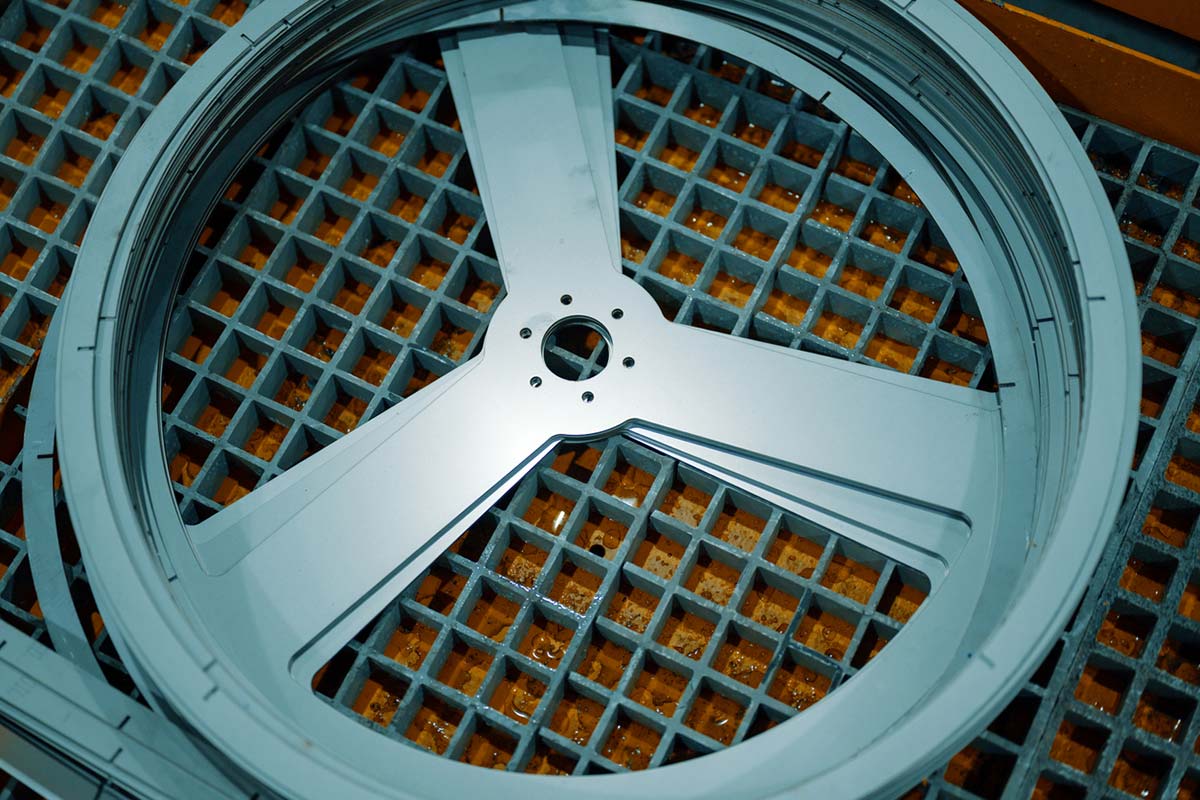

Explore the expansive possibilities of thermoforming.

Thermoforming is a process that heats up plastic sheeting to a temperature that makes it pliable and able to be formed with a mold. After the plastic is molded, the excess is trimmed to create the finished product. Large, flat products are the best candidates to be created via the thermoforming process whereas smaller, high volume parts are best suited to the injection-molded process.

The thermoforming process has a wide array of product possibilities beyond the material handling solutions that TriEnda produces today. Explore the expansive possibilities of thermoforming.

Yes, it CAN be thermoformed:

- Recreational equipment like canoes, kayaks, sleds, and more

- Sunroofs

- Large, exterior vehicle body panels

- Exterior Mudguards

- Underbody debris protection panels

- Headliners

- Storage tubs

- Pillar covers

- Bunks

- Cabinet Systems

No, it CAN’T be thermoformed:

- Small latches

- Handles

- Door pulls

- Small plastic pieces for gauges, closures and components

- Insulators

- Gaskets

There are many products that lend themselves well to the thermoforming process and some that are more suited to being created via the injection molding method. If you are wondering if the product you have in mind would be a candidate for the thermoforming process, reach out to our experienced sales team to learn more.