Automotive Plastic Pallets

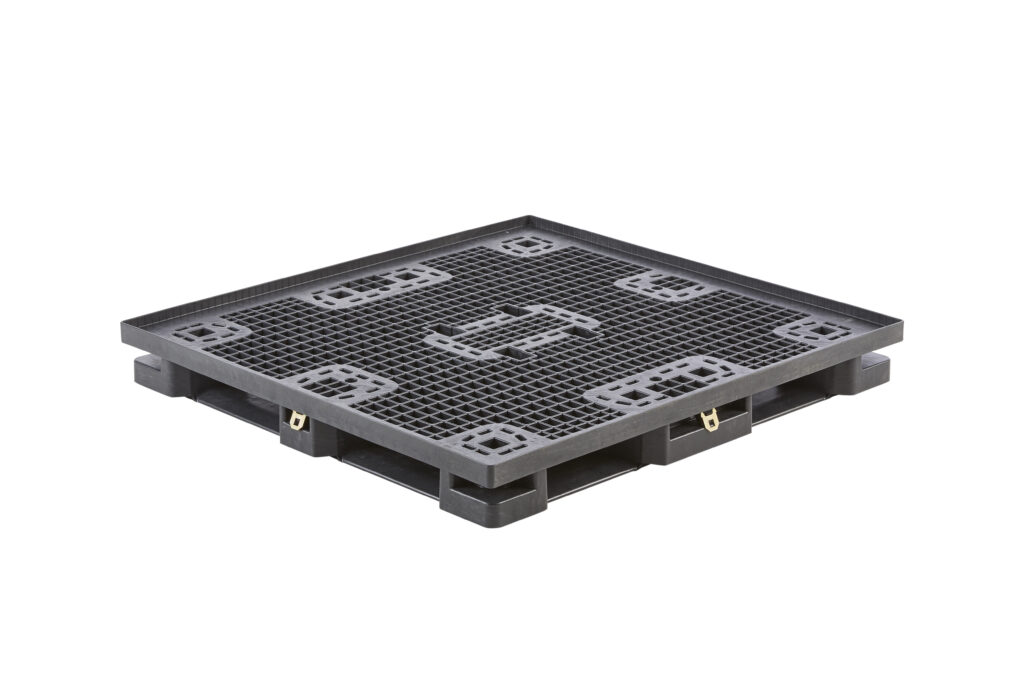

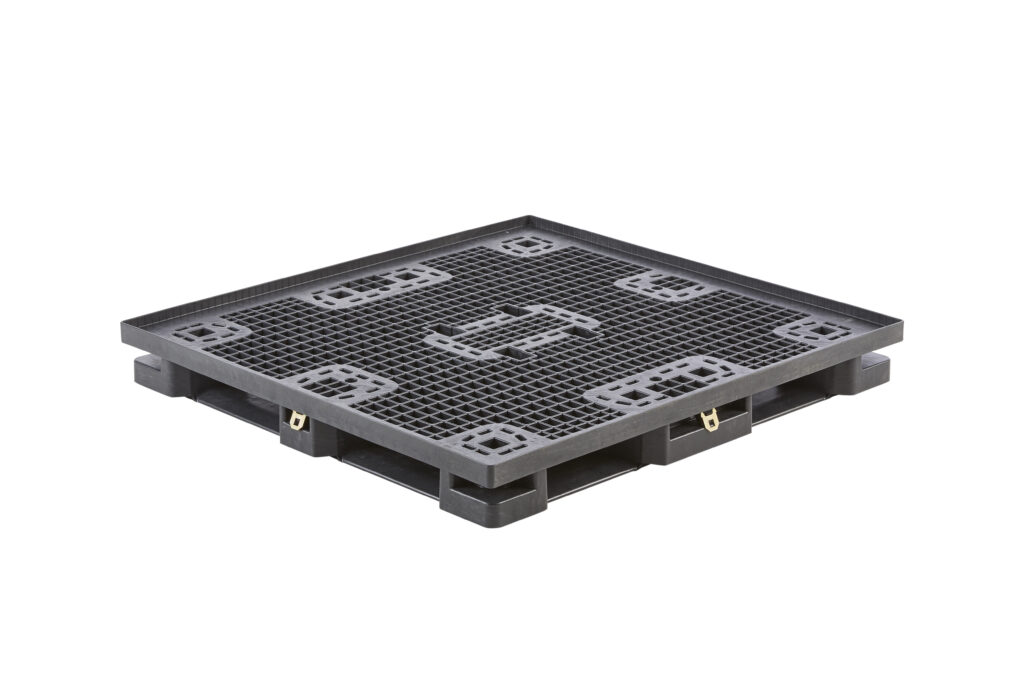

Thermoformed HDPE Twin Sheet Construction

The high-density polyethylene (HDPE) twin sheet construction of our automotive plastic pallets provides durability and longevity. Easy-grip loops and a 4-way forklift and forkjack entry allow for improved mobility and use. An anti-jam feature keeps nested pallets from resting on retractors during return shipments. Constructed with a mirror image design, automotive plastic pallets are fully nestable to conserve storage space and reduce shipping costs. With manufacturing operations in both the United States and Mexico, we offer a dependable, scalable solution to support automotive needs.

EASY CLEAN

RECYCLABLE CRADLE TO CRADLE

Sanitary

Weather resistant, withstands humidity

Impact resistant for long cycle life

4-Way Forklift & Forkjack Entry

TriEnda’s automotive plastic pallets are engineered solutions for high-volume production, distribution, and global shipping. Every pallet delivers strength, efficiency, and longevity.

Light Duty (44.25×48):

- Durable thermoformed HDPE twin-sheet construction with a mirror-image, nestable design conserves space and improves return shipping efficiency. Anti-jam technology prevents pallets from resting on retractors, and easy-grip loops plus 4-way forklift/forkjack entry make handling simple. Optional cargo belts, interlocking trays, and identification labels add flexibility for automotive and industrial use.

Medium Duty Pallet (46.5×49.5):

- Engineered for medium-weight loads, this pallet features anti-jam design, a mirror-image nestable structure, and is conveyable. It accommodates triple-wall corrugated sleeves for added load stability. Easy-grip loops, 4-way forklift entry, and optional cargo belts, interlocking trays, and identification labels make it ideal for midsize vehicle components and industrial distribution.

Heavy Duty Pallet (45×48):

- Built for high-weight, heavy-duty loads, this pallet combines mirror-image nestable design with anti-jam technology for safe, efficient storage and transport. Thermoformed HDPE construction delivers durability, while easy-grip loops, 4-way forklift entry, and optional cargo belts, interlocking trays, and identification labels make it suitable for large automotive assemblies and industrial applications.

Injection Molded Pallet (45×48):

Heavy-duty injection-molded pallet with full-coverage lid, designed for high-weight loads. Compatible with competitive models, nestable, rackable, and conveyable. Optional cargo belt & buckle, identification labels, and ink stamping make it ideal for automotive, industrial, and warehouse use.

01 /

Automotive Pallet Options

Light duty

Nestable thermoformed HDPE pallet measuring 44.25″ × 48″ × 5.5″ and weighing 20 lbs (9 kg).

Features anti-jam design, easy-grip loops, and 4-way forklift entry. Optional cargo belts, interlocking trays, and labels provide flexible handling for automotive and industrial use.

medium duty

Nestable pallet for medium-weight loads, measuring 46.5″ × 49.5″ × 7.63″ and weighing 30 lbs (11.6 kg).

Supports triple-wall sleeves, includes easy-grip loops, 4-way forklift entry, and optional cargo belts, interlocking trays, and labels for midsize automotive and industrial applications.

heavy duty

Durable thermoformed HDPE pallet for high-weight loads, sized 45″ × 48″ × 6.63″ and weighing 25.5 lbs (11.6 kg).

Features anti-jam design, nestable construction, and optional cargo belts, interlocking trays, and labels, making it ideal for large automotive assemblies and industrial use.

Injection molded

Durable injection-molded double deck pallet with single sheet lid, designed for high-weight loads, sized 45″ × 48″ × 6″. Pallet weighs 65 lbs (29 kg); lid weighs 18 lbs (8 kg). Rated for 10,000 lbs (4,536 kg) dynamic and 40,000 lbs (18,144 kg) static loads.

01 /

Features & Benefits

United States and Mexico Manufacturing

- Manufactured in the U.S. and Mexico for a dependable, scalable supply.

Stackable, Nestable, Conveyable

- TriEnda automotive pallets are engineered for high-volume production and distribution environments where efficiency, safety, and repeatability matter. Each pallet streamlines handling while protecting components from damage.

Anti-Jam Design for Smooth Nesting

Prevents nested pallets from resting on retractors during return shipments, improving warehouse safety, reducing handling errors, and maximizing storage efficiency.

Mirror-Image Nestable Design

Fully nestable pallets conserve space and reduce shipping costs. Mirror-image construction ensures consistent stacking and stable handling across light-, mid-, and heavy-duty pallets.

4-Way Forklife & Forkjack Entry

Easy-grip loops and 4-way entry allow flexible, ergonomic handling by forklifts or forkjacks, reducing manual lifting and improving safety and material flow.

Optional Cargo Belts, Interlocking Trays & Identification Labels

Secures loads, streamlines inventory tracking, and integrates seamlessly with warehouse operations for versatile handling.

Drain & Hand Holes for Safety & Sanitation

Integrated drain and hand holes improve ergonomics, facilitate cleaning, and manage moisture during outdoor storage and transportation.

Conveyable & Automation Ready

Smooth base geometry and consistent dimensions allow reliable movement on conveyors and robotic systems, reducing manual handling and supporting high-speed automated operations

Light, Medium, Heavy Duty, and Injection Molded Options

Available in sizes and capacities to handle light loads, medium-weight components, and heavy-duty assemblies, providing a flexible solution for automotive and industrial supply chains.

Our automotive pallets are designed to protect product, optimize material flow, and deliver long-term value in production and logistics operations.

Contact our team to discuss sizing, customization options, and program-specific solutions.

02 /

Gallery

FAQ: Why Use Automotive Plastic Pallets?

What materials are TriEnda pallets made from?

The pallets are made from durable high-density polyethylene (HDPE), engineered for long-term use in automotive production, distribution, and warehousing. However, we do offer injection-molded options.

Are the pallets nestable and stackable?

Yes. The automotive pallets feature mirror-image nestable designs and anti-jam technology, allowing for safe stacking and space-efficient storage.

What sizes and weight capacities are available?

Light-Duty Pallets: 44.25″ × 48″, 20 lbs (9 kg) – small loads

Mid-Duty Pallets: 46.5″ × 49.5″, 30 lbs (11.6 kg) – medium loads

Heavy-Duty Pallets: 45″ × 48″, 25.5 lbs (11.6 kg) – high-weight loads

How do I know what size fit my needs?

Choosing the right pallet depends on the weight, size, and type of your loads.

Light-Duty Pallets are ideal for smaller components and lighter automotive parts.

Mid-Duty Pallets handle medium-weight assemblies or midsize loads.

Heavy-Duty Pallets are built for large, high-weight components.

Consider your handling methods, storage space, and automation requirements. For specialized applications or extra durability, injection-molded pallets are also available. Contact our team to discuss your load specifications and find the perfect solution.

Can these pallets be used with forklifts and other material handling equipment?

Yes! They have 4-way forklift and forkjack entry along with easy-grip loops for safe, ergonomic handling.

Are there options for securing loads on the pallets?

Yes. Optional features include cargo belts, interlocking trays, and identification labels, helping keep loads secure and organized during transport or storage.

Are these pallets compatible with automated systems?

Yes. Their consistent dimensions and smooth bases allow reliable use on conveyors, robotic handling systems, and automated warehouses.

Are there options for heavier-duty applications?

For applications needing extra strength or long-term durability, TriEnda offers custom injection-molded pallet options.

Are the pallets easy to clean and maintain?

Yes. The HDPE construction is easy to clean, sanitary, and resistant to impacts and weather, making them ideal for industrial environments.

How can I get more information or request a quote?

Contact our team to discuss sizes, duty ratings, customization options, and program-specific solutions for your operation.