TriEnda Metal Racking

Custom Returnable Metal Racking Manufacturer for Automotive OEM & Tier Suppliers

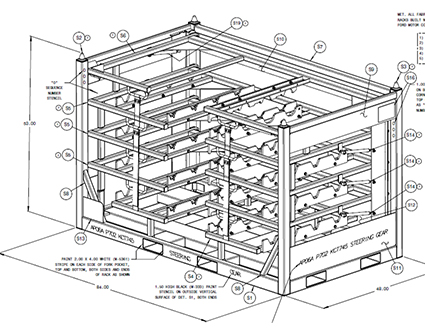

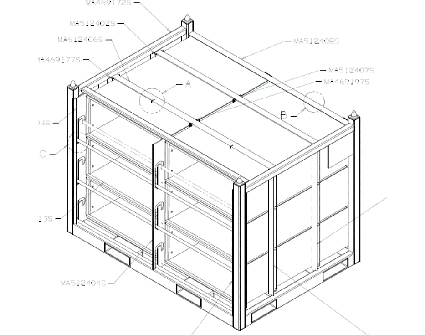

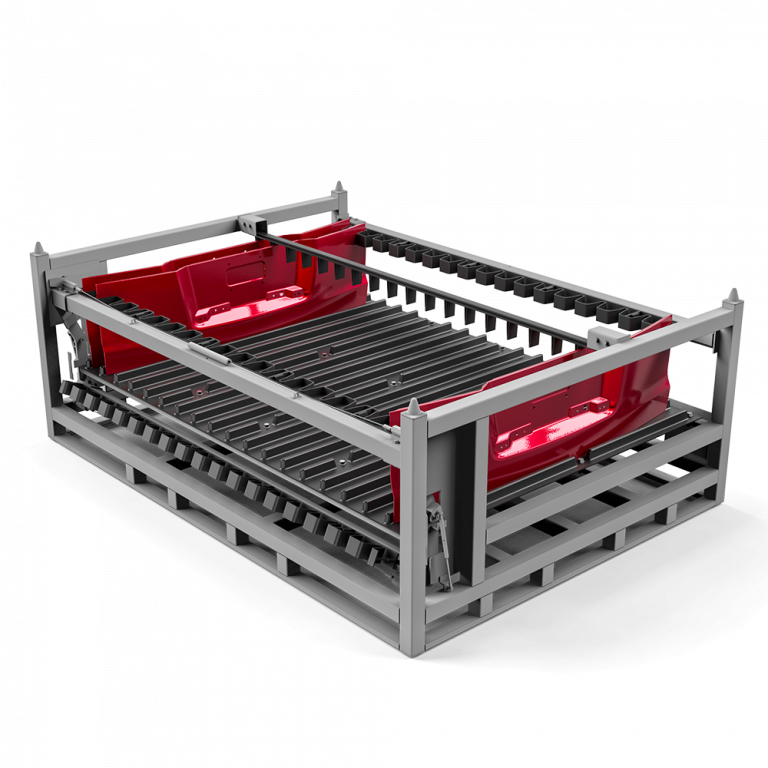

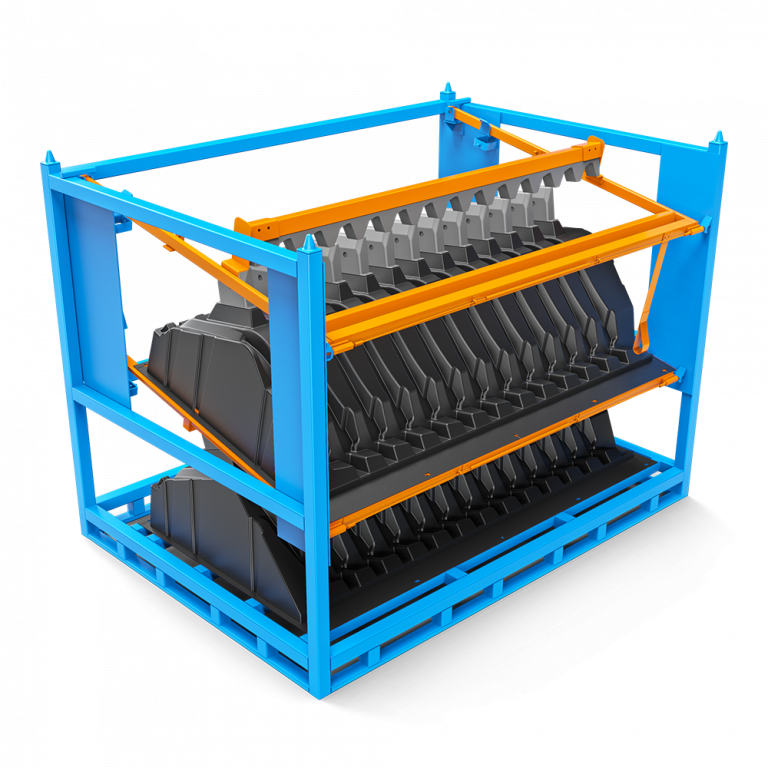

STEEL RACKING FOR AUTOMOTIVE COMPONENTS

TriEnda provides custom-designed steel racks for the automotive industry. Steel racks are the most efficient and durable way to transport heavy automotive parts within your manufacturing footprint.

TriEnda’s custom racks are designed to safely and efficiently accommodate heavy loads, such as engines and transmissions. With TriEnda’s extensive design and engineering capabilities, we can create a solution that meets the needs of your next project.

TriEnda can provide rework and repair for your existing racking. Save thousands of dollars in refurbishment by utilizing our expertise

OEM PREFERRED SUPPLIER

TURN KEY MATERIAL HANDLING SOLUTIONS

IDEAL TEXAS MANUFACTURING LOCATION

CONCEPT AND DESIGN SERVICES AVAILABLE

01 /

Metal Racking Applications

TriEnda metal racking solutions are precision-engineered steel returnable racks designed for automotive OEMs, Tier 1 suppliers, and high-volume manufacturing operations. Built in our Arlington, Texas facility, our custom metal racks combine heavy-duty construction with short lead times and a strategic location that supports just-in-sequence delivery, reduced freight costs, and faster program launches. TriEnda racks are engineered to protect complex automotive components including engines, transmissions, battery systems, stamped parts, body panels, interior assemblies, powertrain components, and EV modules, while optimizing storage and material flow across the supply chain.

02 /

Gallery

02 /

Features & Benefits

TriEnda automotive metal racking systems are engineered for OEM and Tier supplier manufacturing environments that demand durable returnable packaging, precision part protection, and automation-ready logistics. Designed for high-cycle automotive production, our custom steel racks improve material flow, protect Class A surfaces, and lower total packaging cost across the automotive supply chain.

Features OF TriEnda Metal Racking

Heavy-duty welded steel construction-Built for constant forklift handling and high-cycle automotive use.

Custom engineered dunnage-Protects Class A surfaces and precision components in transit.

Stackable rack design-Maximizes vertical storage while maintaining load stability and saving floor space.

Automation-compatible footprint-Integrates with conveyors, AGVs, and robotic handling systems.

Modular multi-SKU layouts-Supports mixed parts, kitting, and sequencing operations.

Returnable packaging system-Designed for closed-loop automotive logistics.

Corrosion-resistant finish-Extends rack life in harsh plant environments.

Forklift & tugger ready Compatible with standard plant material handling equipment.

Benefits of Using TriEnda for your Metal Racking Needs

Strategic Texas Location-Central positioning supports major automotive manufacturing corridors.

Short Lead Times-Rapid production keeps programs on schedule.

Custom Engineering Services-Racks designed around exact part geometry.

Faster line-side efficiency-Improves part presentation and assembly flow.

Reduced part damage-Minimizes vibration, abrasion, and impact risk.

Lower total packaging cost-Cuts expendable packaging and replacement spend.

Streamlined logistics-Improves trailer cube and transport efficiency.

Sustainability gains-Eliminates disposable packaging waste.

Built for automotive cycles-Withstands high-frequency production demands.

Scalable for program growth-Adapts to new parts and ramp-ups.

Strategic Texas Location-Central positioning supports major automotive manufacturing corridors.

Short Lead Times–Rapid production keeps programs on schedule.

Custom Engineering Services-Racks designed around exact part geometry.

FAQ: Why Use TriEnda Metal Racking and Shipping Containers?

What is automotive metal racking used for?

Automotive metal racking is used to safely transport, store, and stage heavy or precision components such as engines, transmissions, EV battery systems, stamped parts, and Class A assemblies. Returnable steel racks protect parts during shipping while improving material flow inside OEM and Tier supplier plants.

What types of automotive parts can TriEnda metal racks hold?

TriEnda racks are engineered for engines, powertrain components, EV batteries, body panels, interior assemblies, stamped parts, castings, and mixed-SKU programs. Each rack is custom designed around the part geometry to prevent damage and maximize density.

Are TriEnda metal racks returnable and reusable?

Yes. TriEnda metal racking is built for closed-loop automotive logistics. Heavy-duty welded steel construction allows racks to withstand repeated shipping cycles, reducing expendable packaging waste and lowering total packaging cost.

How do custom metal racks reduce part damage?

Custom dunnage, precision fit supports, and engineered load distribution prevent vibration, abrasion, and impact damage. This is especially critical for Class A surfaces and high-value components in automotive production.

Can TriEnda racks integrate with automated material handling systems?

Yes. TriEnda racks can be designed for conveyors, AGVs, robotic loading cells, and automated storage systems. Automation-ready footprints help future-proof manufacturing operations.

What are the benefits of manufacturing metal racks in Texas?

TriEnda’s Arlington, Texas facility provides a central location for North American automotive manufacturing. This reduces freight distance, shortens transit time, and supports faster program launches.

How fast are TriEnda metal rack lead times?

TriEnda offers short lead times thanks to in-house engineering, fabrication, and assembly. Faster turnaround helps automotive programs stay on schedule and reduces supply chain risk.

Why choose returnable metal racking instead of expendable packaging?

Returnable metal racks lower long-term packaging costs, improve sustainability, and provide consistent part protection. They also simplify plant handling and reduce waste compared to disposable packaging.