How Computer-Aided Design Programs help create every product at TriEnda.

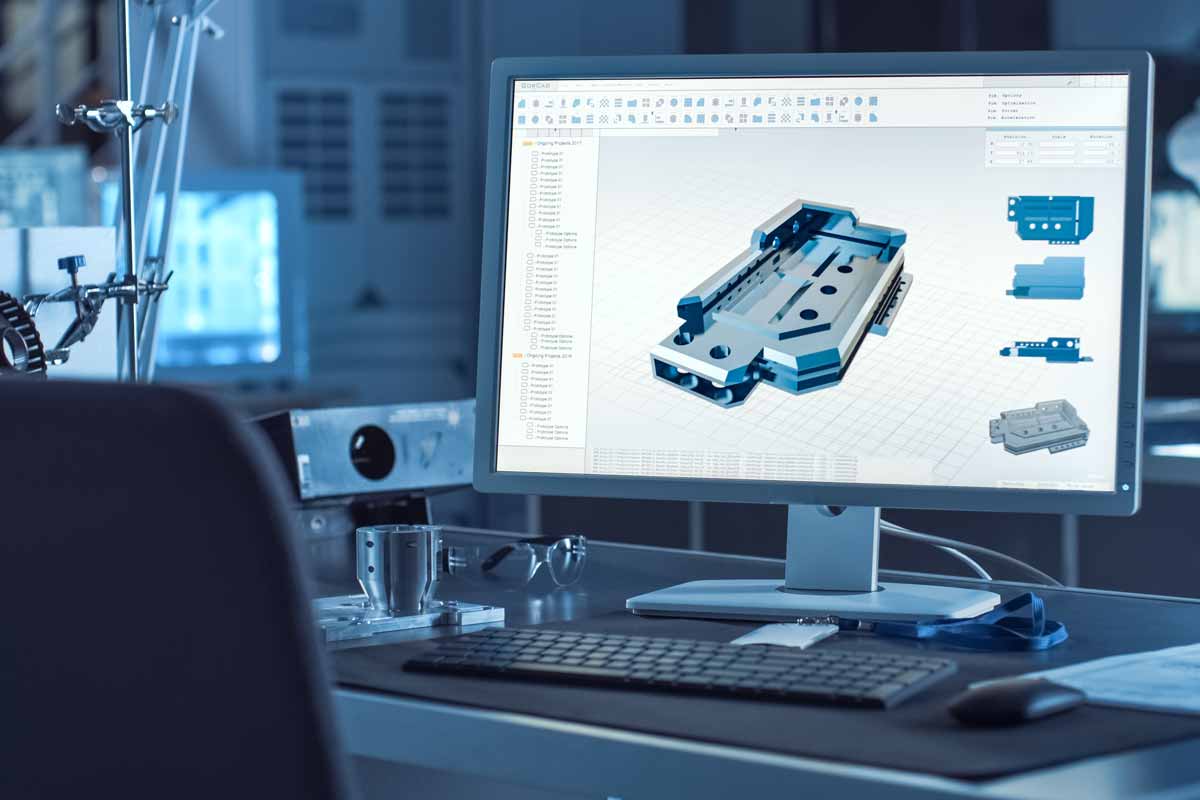

A significant part of our design process here at TriEnda is the creation of a product design in a Computer-Aided Design (CAD) program like Solid Works, Seimens NX, or Catia. CAD is a vector-based software that allows engineers to design product outlines in a three-dimensional virtual environment.

At its base, designs in CAD are math data, “This data is a mathematical representation of a part in the physical world,” Senior Design Engineer, Chad Dimock said. “CAD creates a virtual representation of a part. It has size and shape and can be made as an assembly with custom parts. It can be measured and added to simulations to make sure it will meet requirements.”

When the TriEnda team works on a project for a specific customer we start with understanding the need, this means that if we are creating packaging for a specific product, we put together all of the information, dimensions, and testing requirements for that product. From there, our design engineers work in CAD to design a packaging solution that will fit the product perfectly and stand up to rigorous testing. “The first step is to get all of the product information from the customer so we can make sure we create a design that meets the need of the product and the customer.” Design Engineer, Thomas Bloom said.

When our team creates a completely new product to the market, our design engineers work with the New Product Development team. They discuss what the product should look like, how it should function, and what testing it needs to pass to meet our quality standards. “When we create a design for a new product we don’t start from scratch. We start with research and a joint effort between NPD, Studio 540, and Engineering to create a basis for the outline,” Thomas Bloom said. From there engineering uses CAD to assign dimensions, weight, and thickness to the outline until it creates our first three-dimensional product model.

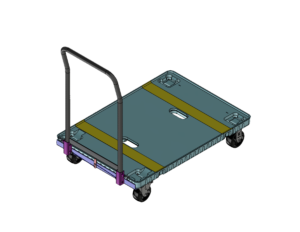

Now, we briefly mentioned the cross-over between engineering and our in-house design team, Studio 540, above. Studio 540 uses these CAD designs from engineering in the next step of our process. Once engineering has created the product design, the CAD file is handed over to our industrial designers to take that math data a step further. Studio 540 designers focus on the visual impact of the product in addition to the functionality, they do this by creating realistic rendered images of the product by working off the CAD data. This means adding texture, color, grooves, hardware, accessories, and many more features to transition this item from a mathematical outline to a realistic product image. “Design as we know it would not exist without CAD. CAD allows engineers and designers to accurately build any conceivable 3D shape exactly as it will appear in the real world. In the past, this process required sluggish methods such as manual drafting, hand-sculpting and model making. The development of CAD technology has exponentially increased the efficiency of design and engineering,” Industrial Designer, Alex Greene said.

Once the math data and industrial design artwork have been combined, tools are designed in CAD by our engineering group and sent to the toolmaker to be cast. The production team then gets to work on samples and product testing. This process can be repeated several times for a single product if necessary and CAD designs are often edited, revised, and re-done before a final product is created. While the design process has many steps, CAD helps to join design and data, “The most important step in a design is the match between concept and reality. This is the point at which the dream of the idea meets reality in an engineered concept. When the bugs of the design are worked out in CAD and the part can be created that is the ‘AHA!’ moment where the customer, the designer, the engineer, and the sales representative breathe a sigh of relief knowing that what they want is achievable,” Chad Dimock said.

The design process has come a long way over the years and employing CAD in our engineering and design departments has allowed TriEnda to break ground into new industries and create products faster than ever before. If you would like to work with someone on our design or engineering teams for your next project, feel free to contact us today!